Marking

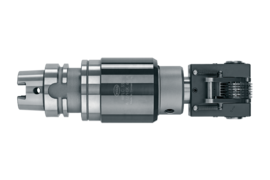

Engraving Chuck ET0

APPLICATION

Application: Marking tool for marking workpieces in the work process

DESCRIPTION / QUALITIES

Advantages

- Long life

- No damage or weakening of the surface

- No burr formation

- Marking of sandblasted surfaces with a hardness of up to 57 HRC possible

- Quick and silent engraving during the production process

- Can be changed like a normal tool

- For all standard holders and materials

Safety parts such as ABS brake parts for cars must be clearly identified due to product liability reasons. These parts are normally manufactured completely on machining centers and the marking will be done during the production.

The BILZ special tool holder ET0 can be changed like any other normal tool into the machine spindle. The ET0 has a spindle with ball bearings and an axial way of 10 mm with a specified force.

With suitable feed of the machine spindle the ball pen is pressed into the surface of the workpiece and through the machine program each required marking can be written. The ball pen is clamped in a Rubber Flex® collet and easy to change.

All standard machine connections are available on request.

Example

For almost any material

plastic, aluminum

or hardened steel

(max. 57 HRC)

Cleaning with compressed air

Due to the specifically

targetted compressed air

channels around the

engraving point, our engraving

chuck achieves excellent

cleaning results – even with fine chips.