Bilz News

product information

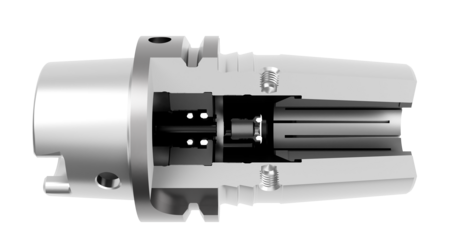

ThermoGrip® TEX

TEX shrink fit chucks offer unrivalled clamping forces and superior damping properties.

- EXtreme clamping forces (Ø16mm over 960Nm)

- Excellent damping properties

- Compact design for maximum rigidity

Click here for the product

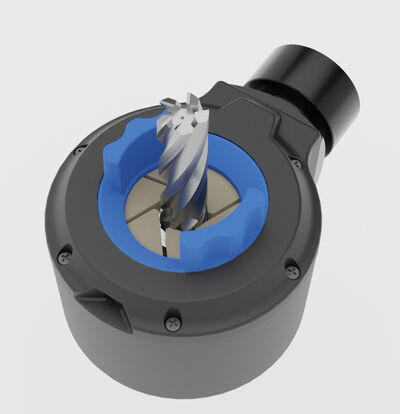

Smart GNCK - The future of tapping

Monitoring and optimisation with smart technology

Product description:

The Smart GNCK is the latest innovation in threading technology. This state-of-the-art device monitors operating times in real time to ensure maximum efficiency and precision. Thanks to its intelligent sensor technology and user-friendly interface, users can accurately track and optimise tool uptime and wear.

Click here for the product

Discover our latest cooling units!

We are pleased to announce the launch of our latest innovations in the field of cooling units: the CC1200 contact cooler and the LC1200 liquid cooler.

Contact Cooler CC1200

- Stand-alone version: perfect for flexible applications

- Gentle on tools: Two force-guided contact coolers prevent damage

- Comprehensive set: Includes active cooler and five cooling inserts (diameter 6-32 mm)

LC1200 liquid cooler

- Maximum cooling length: 350 mm with HSK-A63

- Efficient liquid cooling: Fast cooling times and easy handling.

- Fully equipped: Includes coolant concentrate, compressed air gun and tool holder

Experience the future of tool cooling with Bilz. Stay cool and productive!

Find out more and order now!

The new IRIS induction coil

Product description:

The IRIS generation is the latest innovation in the field of ThermoGrip shrink-fit technology. With its user-friendly design and advanced functions, the IRIS generation sets new standards in operability. This technology has been developed to fulfil the requirements of modern manufacturing processes while reducing operating costs.

Click here for the product

ThermoGrip® TMG

- One Basic holder for all diameters

- The new Bilz TMG clamping system combines the strengths of shrink clamping technology

with the flexibility of collet solutions. - Extreme holding forces - Exceptional flexibility, high rigidity and

optimized vibration damping characterize our new TMG

For the product please click here

entry-level shrink fit machine ThermoGrip® ISG 1200

- 20% less energy consumption with comparable performance

- Easy input of shrink parameters by scanning barcodes

- Clamp your tools safely and quickly - for more efficiency in your

production

For the product please click here

S3D Synchro

- Minimum length compensation in compression and tension direction

- Ball bearing mounted (i.e. torque independent) suspension

- 100% SCK kompatibel

For the product please click here

ThermoGrip® Corona Jet 2.0

- Targeted coolant supply, resulting in greater efficiency

- Tried and tested ThermoGrip® geometry

- Chip evacuation is optimised because of coolant flushing from cutter flute chambers, ensuring improved chip removal

For the product please click here

ThermoGrip® BIONICS

- Shrink chucks with bionic structural optimisation

- Form optimisation leads to an increase in the life and

load capacity of the holder through a uniform structure throughout. - Perfectly suited for our Thermogrip® shrink machines

- Smooth, silent running due to “Balanced by Design” and subsequent fine balancing

For the product please click here

The new Bilz Engraving Chuck ET0

- Engraving on almost any surface and various materials such as plastic / aluminum / steel (max. 57 HRC)

- Adjustable engraving hardness (engraving depth)

- Adjustment of the preset (max. 5 mm) by adjusting the setting screw

- Despite the compact design, it is suitable for many different applications

For the product please click here

The new Touchdisplay for Thermogrip®Shrink Machines

- Maximum productivity using the favourites list or by calling up previous entries

- reading data chips or using optical codes

- This interface offers many possibilities forexperts to define and store their own processes

Thermal tool clamping meets Industry 4.0

- SAFETY

Automatic shrinking and cooling - TIMESAVING

Heating in seconds: the tool slides into the heated toolholder and is automatically centred in the BILZ

ThermoGrip® shrink chuck - SMART NETWORKING

TDSc reader and machine software implement Industry 4.0 in your processes and tool management

For the product please click here

Pre-Paid Pre-Paid Solution for Thermal Clamping

- No investment costs for

the shrinking device - Flexible terms

- No risk of amortization

- Prepaid solution for full

cost control: Only pay for

what you use!1

For the product please click here

Tapping attachment for lathes GNCN

- Reduced throughput time - Designed for high cutting speeds

- 40 times less power consumption - Constant cutting speeds of the spindle minimise energy consumption

- Process reliability - Technically sophisticated with tension compensation and ball notching system, the GNCN works with a minimum thread depth tolerance of +/-0.15 mm

- Double the service life - 250,000 threads guaranteed to be cut maintenance-free

- Modular design - therefore machine-specific customisation possible

click here for the product

Super Collet Chuck

- Excellent Run-out accuracy within 5µ @ 4D

- Gripping force double than ER

- Integrated run-out accuracy with compact design

- Minimize the work interruption between tool and work piece

For the product please click here

Configurator for shrink units

Configure your unit to match your requirements and ask for a personal quotation:

- All units at a glance

- Quick selection of all possible configurations

- For beginners and experts

For the product please click here

AOCS

With the Automatic Orientating Clamping System tools can be changed fully automated during the machining of tools with industrial robots.

- Makes clutching and declutching of processing tools possible

- Independent of the rotational position of the spindle

- Coupling can be effected via a tension or also via a shift sleeves

- Better sealing compared to actual quick-change systems

continue to the product and click here

STA Synchro Tap Adaptor

The new STA Synchro Tapping Adaptor was designed specifically for ER collet chucks and allows for synchronous thread cutting and forming to be archieved with all suitable machines.

- high productivity due to fast tool change times

- significant increase in tool life and process reliability

- reduced risk of tool breakage

- cost savings due to reduced tap inventory

- reduced spindle wear

- increase in process reliability

continue to the product and click here

Expansion of the VIDAT programme for shell milling cutters

ThermoGrip® VIDAT stands for VIbrations DAmping Technology from BILZ

Vibrations caused during the first extension deflection are effectively absorbed by means of integrated dampers. VIDAT extensions achieve damping rates of at least 4dB in comparison to normal extensions.

The very rigid nature of the shrinking process means that long, slim extensions in particular have a tendency to chatter and vibrate. VIDAT extensions reduce this effect, thus considerably increasing the area of application.

continue to the product and click here

BPMS- Pneumatic Measurement System

System Structure for Process Meaurement

A fine machining process like honing is usually one of the last processing steps in the fabrication of forms, which includes certain tribology and dimensional precision properties. A precise control of the process is necessary. The measurement system from Bilz enables the integration of the honing process in machining centres. Honing tools with pneumatic measurement nozzles are required.

The recorded measured value, usually the diameter, is the criteria that is permanently compared to the requested size. When the measurement value is achieved, the interface communicates the value to the NC-Control which then stops the honing process. Because of this, there is no operator needed to monitor the actual hole size. The communication is made in 4 bit resolution over the PLC and up to 16 commands can be exchanged.

continue to the product and click here

Slim Hi-Power Milling Chuck

Bilz precision branches out into the traditional chucking world.

- Slim design helps to reach depth without fouling

- Powerful and rigid

- Clamping torque is twice that of ER holders

- Run-out consistency, 5 micron at 4D

- Clamping nut without slots makes its usage at higher rpm effortless

continue to the product and click here

TDSc data carrier

ToolDialog Smart connectivity - RFID technology for tool identification

Clever components are intelligently networked and communicate directly with each other via centralised data storage - this is a brief explanation of the term Industry 4.0. Bilz offers a new, cost-effective system as part of these Industry 4.0 activities with its SmartChip.

Transmission in the UHF range in accordance with ISO 18000-6

click here for the product

BTC Presetting Unit

Exciting Products from the Technology Leader

Technology meets modern design in the new Bilz presetter which every production environment can benefit from.

- Increased Productivity Through Higher Machine Uptime

- Quick Familiarization Through Simple and Intuitive Operation

- Increased Cutting Quality on the Workpiece

continue to the product and click here

Corona Jet

A new coolant supply through integrated inclined nozzles

ThermoGrip® Corona Jet offers a new coolant supply through integrated inclined nozzles which are aimed directly at the cutting edge. The dimensions of ThermoGrip® Corona Jet are identical to the standard shrink feed. On the end face of the nozzle ring, the tiny holes of the coolant outlet can be seen. ThermoGrip® Corona Jet like any shrink fit chuck can be used without assembling and disassembling. The tool holders are available in all standard lengths and many diameters.

continue to the product and click here

Contacts

![[Translate to Englisch:] BTC Voreinstellgerät](/fileadmin/_processed_/3/1/csm_Voreinstellgeraete_Zusammenstellung_Deckblatt_64ca1de0c1.png)