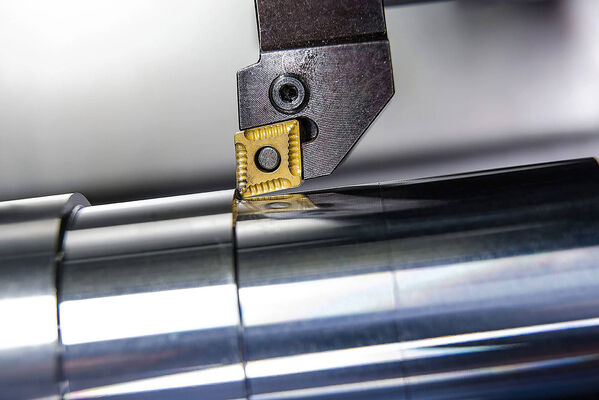

Turning

The ISO turning range with innovative cutting grades and modern geometries turns our customers’ cost spiral downward. Boehlerit offers the optimum indexable inserts for every turning application, e.g. for steel, cast and aluminium machining and the cutting of super alloys with difficult chip formation. Customer-specific solutions complete the wide range of ISO turning solutions.

Milling

The quality standards in milling have been defined by the Boehlerit cutting experts for decades now. The development engineers in the Austrian steel industry town of Kapfenberg put all their technical know-how into a dynamic FEM design (finite-element method) for Boehlerit milling equipment to create stable milling tools with excellent fatigue strength properties, optimum chip formation and precise concentricity characteristics. All tools are nickel-implanted and owe their long tool life to special materials and heat treatments. The basis of the new high-end milling range are 15 innovative tool systems, including multi-purpose tool systems where one base body makes two types of machining possible. This reduces the carrier body costs and saves warehousing expenses. The range includes highly economical high-feed tools and face-milling cutters with 16 edges. A total of 18 milling grades cover all the many milling tasks of face or step milling in all current materials. They combine machining reliability and economic efficiency. Various carbide substrates are used to produce the range of milling grades, or indexable milling inserts, fine-tuned to cover an extensive range of face and step milling operations: from roughing to finishing, from cast to steel, stainless materials and aluminium. The milling grades guarantee minimal wear on free areas and a higher resistance to chipping of the cutting edges. Resistance to thermal cracking or crater wear is also ensured.

Drilling

Specifically adapted to the ever-increasing machining requirements, Boehlerit offers a broadly diversified product portfolio in the drilling sector which, thanks to the optimal design of cutting materials and geometries made from various materials, are used in general mechanical engineering as well as in die and mould making.

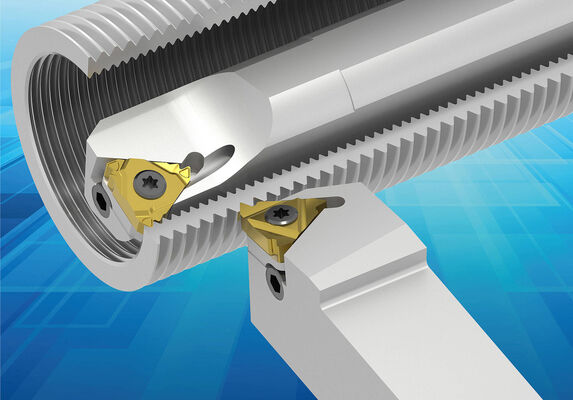

Threading

The Austrian carbide and tool specialist Boehlerit continues to move towards becoming a full-range supplier and develops balanced geometries, with the aim of delivering top performance over a very wide range of materials and applications. This results in efficient and highly productive tool solutions with a comprehensive variety of products.

BOEHLERIT GmbH & Co KG

Werk VI-Straße

A-8605 Kapfenberg / Österreich

Tel.: +43 (3862) 300-0

Email: info@boehlerit.com