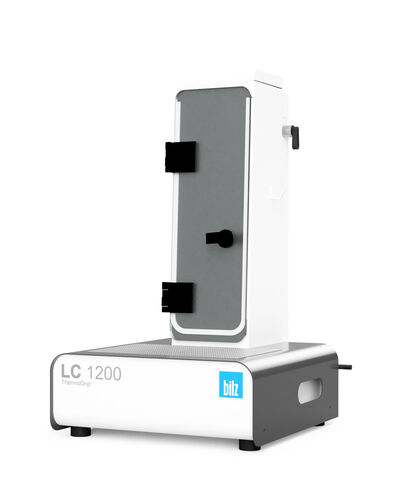

Advanced cooling solutions with the LC1200

Efficient liquid cooling for your shrink fit chucks

Product description

The LC1200 cooling element is the latest innovation in the field of liquid cooling for shrink fit chucks. With its advanced cooling technology and user-friendly features, the LC1200 Liquid Cooler sets new standards in cooling. Designed for maximum efficiency and ease of use, this cooling unit offers a reliable solution for a wide range of industrial applications.

Main features

- Maximum cooling length: Up to 350 mm with HSK-A63, ideal for long tools.

- Hinged lid: Enables easy cooling of long tools without additional modifications.

- Liquid cooling: Fast and effective cooling in just 40 seconds.

- Scope of delivery: Includes 1 litre of coolant concentrate and compressed air gun.

Technical data

- Item number: 5205712 (ISGK1250-L;Liquid cooler)

- Cooling time: 40 seconds (short & long)

- Compressed air: At least 4 bar

- Power supply: 230V / 50Hz

- Dimensions (W x D x H): 415 x 480 x 710 mm

- Weight: 24 kg

Advantages

- Efficient cooling: The LC1200 cools tools quickly and evenly, resulting in a longer tool life and improved production quality.

- Easy handling: The hinged lid and user-friendly design make operation quick and easy.

- Cost efficiency: Effective cooling and the prevention of mould overheating reduce operating costs and increase productivity.

- Flexibility: The cooling element is suitable for a wide range of moulds and applications, making it a versatile solution for the industry.

- Reduction of non-productive time: Cooling tools in seconds significantly reduces non-productive time.

- No need to actively cool down the emulsion: Saves time and simplifies the cooling process.

- No power consumption due to additional cooling unit: Reduces energy costs and improves the environmental balance.

- Protection and care against corrosion: The tools and shrink fit chucks are protected against corrosion, which extends their service life.

- No damage to the tool cutting edge: The cooling units do not damage the tool cutting edge, which preserves the quality of the tools.

- No additional cooling accessories: No need for additional cooling accessories for different shrink fit chuck outer geometries, which simplifies handling and reduces costs.

How it works

- Installation: The LC1200 liquid cooler is simply integrated into existing shrink fit units and is immediately ready for use.

- Cooling process: Shrink fit chucks with tools are placed in the cooling element and cooled evenly within 20 to 40 seconds. The hinged lid also allows long tools to be cooled.

- Maintenance: The LC1200 is maintenance-friendly and easy to clean. The coolant can be replaced quickly and easily.

Discover the performance of the LC1200 and optimise your tool cooling.

Contact us today for more information!

Contacts