Profile machining / polygonal drilling

Polygon or free-form shapes with the Formbore system tool

Field of application Application

Application: Whether broaching, eroding or milling - quick changes in the machining process are no problem with Formbore

Machine type: Formbore system tools can be used on milling machines, machining centers, lathes and special machines

Features

- No synchronous adjustment to the machine necessary

- independent of the lathe spindle

- blind hole drilling without residual chips

Advantages

- Permanent dimensional accuracy due to correction of cutting edge wear

- virtually wear-free and maintenance-free operation

- Drastic reduction in machining time

- designed for a wide range of profile shapes and sizes

Description / Features

As adaptable and independent as they are convincing: with Formbore system tools, shaped profiles as well as internal and external contours can be produced for the first time in a wide variety with maximum precision by simply drilling and turning, even on conventional machining centers.

No synchronous adjustment to the machine spindle needs to be calculated and programmed. Formbore system tools can be designed for a wide variety of profile shapes and sizes. They enable changes to be made to the machining process, such as broaching, eroding or milling.

Formbore system tools significantly reduce the machining time compared to conventional methods. They also offer additional advantages such as blind hole drilling without residual chips or permanent dimensional accuracy by correcting cutting edge wear. When used on machining centers and milling machines, the torque supports and the modular tool holders are identical to those of the proven Bilz tapping attachments type GNCK / GNCN.

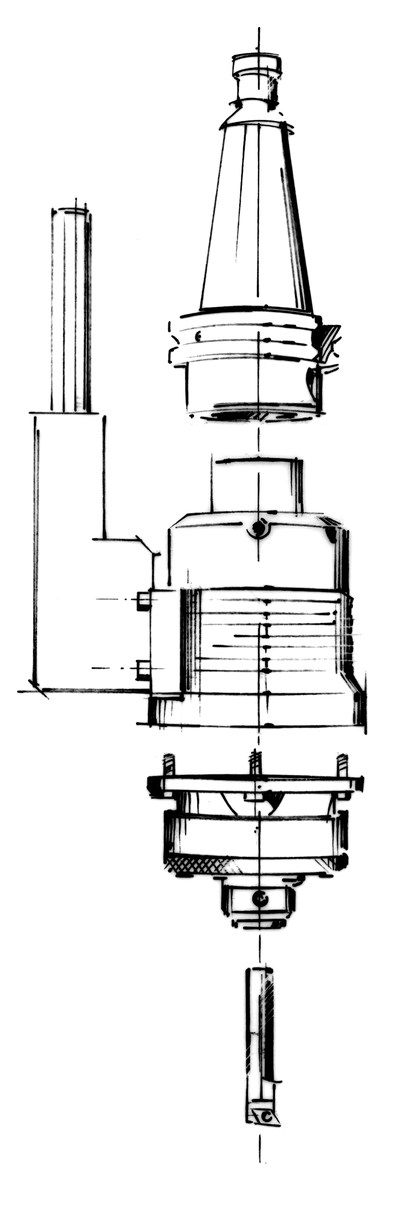

Design and operation of the Formbore system tools

Formbore system tools essentially consist of two components: a drive and the drill head. The rotating drive shaft is mounted in a housing. The torque-supported positive control defines the motion sequence of the drill head. The deflection of the cutting edge is generated by purely rolling elements. Formbore system tools are therefore practically wear-free and maintenance-free. They are suitable for machining almost all materials up to 900 N/mm2 strength.

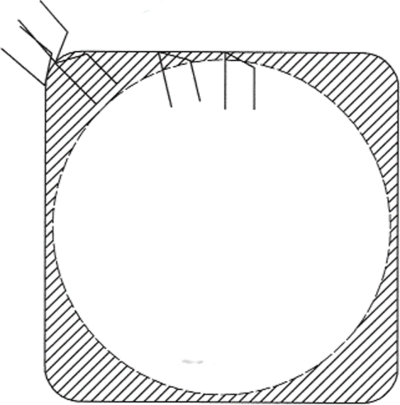

For internal machining, a pilot hole with a maximum diameter of 0.5 mm smaller than the width across flats (SW) is produced first. The actual shaped hole is then drilled in a single operation at a speed adapted to the profile and at a feed rate appropriate to the material.

The Formbore system tool is a system for practical versatility, flexibility, time and cost savings in day-to-day work. Convince yourself of the advantages of Formbore system tools! Tell us your machining requirements and you will immediately receive our tool recommendation.

Frequently asked questions / FAQs

Advantages over pushing

- Flanks are always straight (with butt joints you need a very small angle)

- High surface quality

- Exact contour geometry in tolerance quality H11

- Can easily be used on multi-banc machines (space saving)

- Very low wear of the mechanics

- Clean bore base for blind holes

- Workpiece can be produced in a single clamping operation

Which profiles can the formbore system tool produce?

Standard forms are:

- Square edge

- Hexagon

Semi-standard forms are:

- Surface on cylinder

- Wrench flat

- Octagon

- Polygons

Special forms are:

- Rhombuses

Stars, e.g. dodecagons, can also be produced. A dodecagon star is treated like 2 hexagons, i.e. two cuts are required. After the first cut is completed, the position of the workpiece is adjusted. The workpiece is then finished in the second cut.

What can be processed with the formbore system tool and how?

Depending on the shape and material, the achievable accuracies are up to 0.03 mm

tolerance, measured over the width across flats (SW). The crowning is approx. 0.02 mm.

The corner radii are taken into account as follows:

- Square: corner radius 10 % of SW

- Hexagon: corner radius 4 % of SW

Smaller and larger corner radii are possible and have already been produced. They require individual calculation and testing of the cutting conditions.

Changes to the cutting geometry of the cutting bodies or the boring steels may be necessary. Tests and information on this are provided on specific request (customer drawing required).

For size 1 formbore system tools, the machining depths are max. 35 mm; for size 2, the machining depths are max. 50 mm. For external machining, the customer's requirements must be checked.

The position of the mold can be determined. This means, for example, that it can be determined whether the hexagon is on the tip or on the surface. On lathes, the easiest way to determine this position is by orienting the spindle. The tool can also be easily repositioned in a controlled manner by moving the drive head on the housing.

The dimensions achieved can be corrected. The formbore system tool has a scaled eccentric bush that allows an adjustment of +/- 0.2 mm. For larger shapes, the adjustment can be carried out using a special adjusting screw on the boring bar.

How must pre-machining be carried out before finishing with the formbore system tool?

If a closed profile is required, we recommend going 0.5 mm below the nominal dimension for inner profiles.

below the nominal dimension for internal profiles.

For external machining, the raw dimension should be 0.5 mm above the largest finished dimension.

How many curve blocks and boring bars are required?

It is known that the formbore system tool is a mechanically controlled tool that is deflected by cam blocks.

In principle, a separate cam block is required for each profile and for each size of profile.

Different boring steels or overturning steels must also be used.

However, the same formbore steels can be used for both square and hexagonal and other shapes.

Can the user change the cam blocks himself?

We provide operating instructions for changing curves with the delivery.

The curve change takes approx. 5 minutes.

How does the user know which curve is installed?

There is a display window in the drive head of the formbore system tool. The designation of the cam block is visible there. A coding system has been developed for the cam blocks, which is described in detail on a separate worksheet.

What needs to be considered when using it?

A speed limit applies to formbore system tools.

- Size 1: maximum 1000 min-1

- Size 2: maximum 500 min-1

Note:

The speed limitation applies to both operation and idling!

The latter restriction is particularly important when planning to use a formbore system tool on a lathe that has a turret with central drive.

Are inner and outer contours to be treated equally?

First of all, one and the same formbore drill head and formbore cam block can be used for both internal and external machining of a defined profile.

can be used.

The difference lies in the selection of a formbore boring steel or a formbore overturning steel.

Reduced values must be used for external machining. Depending on the machining process, the overturning length must be partially reduced to keep the tool stable in order to avoid twisting.

Can coolant be used with formbore system tools?

All formbore system tools have a seal that prevents the coolant supplied from outside

from entering the formbore head. This seal also prevents chips from entering.

A variant for internal coolant feed-through is not planned and does not make sense.

Contacts