Smart GNCK - The future of thread cutting

Monitoring with smart technology

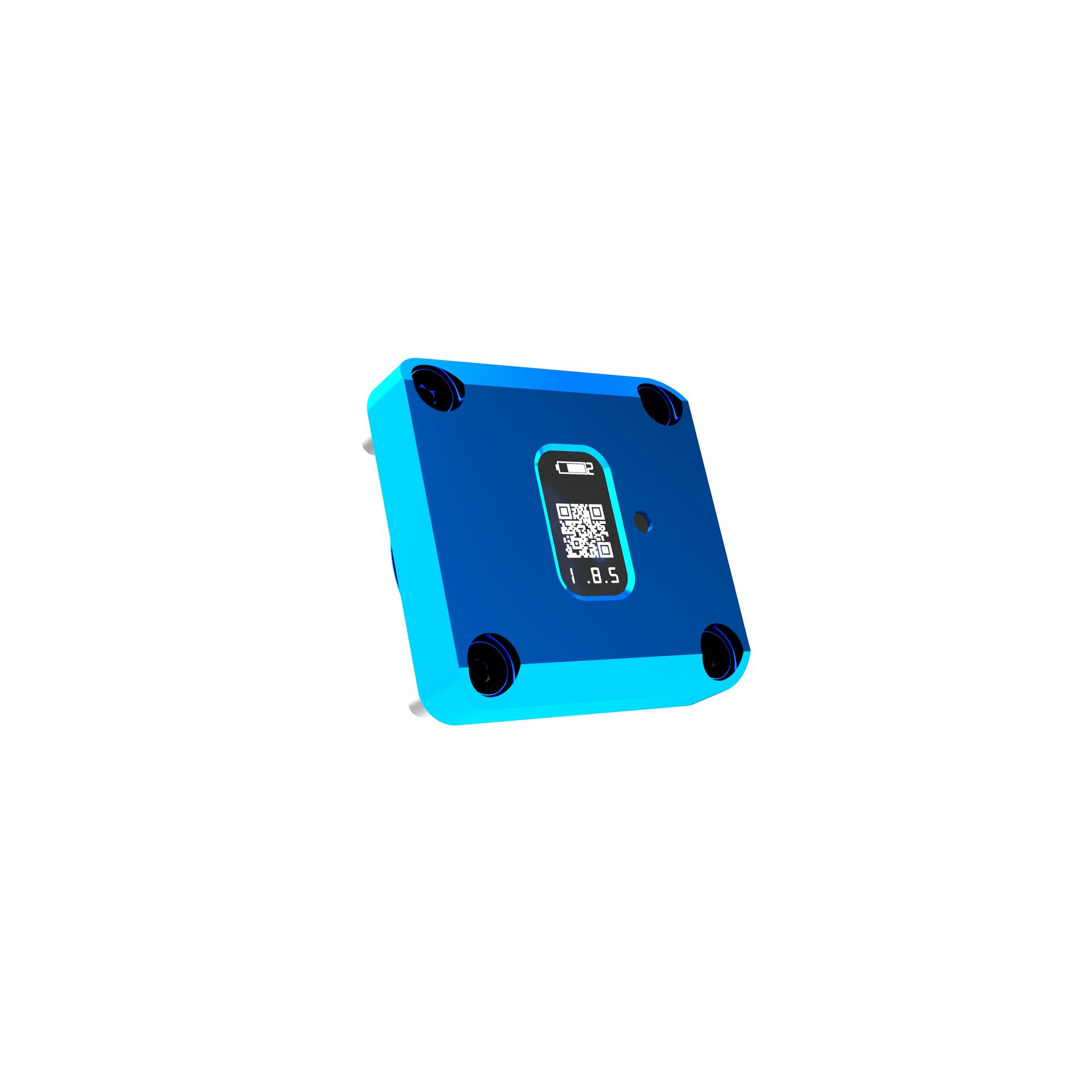

Product description

The Smart GNCK is the latest innovation in threading technology. This state-of-the-art device monitors operating times in real time to ensure maximum efficiency and precision. Thanks to its intelligent sensor technology and user-friendly interface, users can accurately track tool uptime.

Main features

- Real-time monitoring: The Smart GNCK continuously monitors the operating time to enable precise control and planning of maintenance intervals.

- Retrofit options: The device can be easily integrated into existing systems, eliminating the need for extensive retrofitting.

- Ease of use: Thanks to the intuitive user interface, the Smart GNCK is easy to operate and provides a clear display of all relevant data.

Technical data:

- Part number: WA25-IK/HSK-A100-S;Tool holder 5216777

- Monitoring criteria: Number of threads cut, operating time

- Installation: Can be fitted as a retrofit during maintenance or integrated into new orders

Advantages

- Cost savings: By precisely planning maintenance intervals, unnecessary downtime can be avoided and the service life of the tools extended.

- Flexibility: The Smart GNCK is compatible with various machine types and can be integrated into a wide range of manufacturing processes.

Functionality

- Installation and set-up: The Smart GNCK is either installed as a retrofit during maintenance or integrated directly into new orders. After installation, the system is activated and starts monitoring the thread cutting processes.

- Real-time monitoring: Sensors continuously record the operating time and the number of threads cut. This data is clearly displayed in the user interface.

- Maintenance planning: Based on the recorded data, users can plan precise maintenance intervals and thus maximise the efficiency and service life of the tools.

Find out how the Smart GNCK can optimise your manufacturing processes. Contact us today for more information!

Contact person